It is not a secret that the 21st century is the Golden Age for technological advancement. The printing industry has also advanced greatly. When we spoke about digital printing only a few years ago, we were referring to the black-and-white, or, in a best-case scenario, color inkjet printers that were on our desks. Digital printing has its own unique place in printing technology and its share in the market grows every year. Several studies suggest that the share of digital printing in the entire printing industry will reach 21% by 2024. In our humble opinion, it could be even more due to the fact that digital printing is advancing at unprecedented levels.

The label printing competition is between digital and flexographic printing.

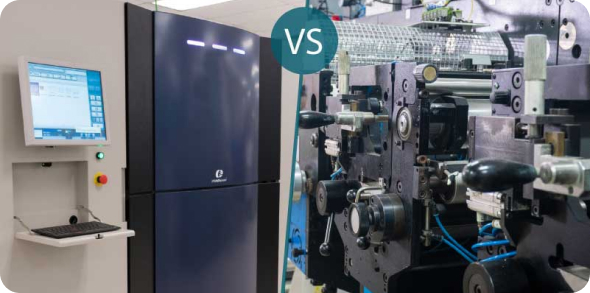

Digital vs Flexographic

In order to understand the difference between these two technologies, it is important to understand what they are and how they work. We will try to explain it as briefly and clearly as possible.

Digital printing uses two main forms of technology: laser printer and inkjet. With digital printing, the image that is to be printed is sent from the computer to the printer. After the appropriate material is set up and the ink is filled (if using an Inkjet) or the cartridge is put in place (if using laser), it is ready for printing. Set-up generally takes around 3-5 minutes.

Everything is a bit more difficult with Flexo. First, flexible printing plates need to be prepared with every layout. These are going to be placed around special cylinders for all colors. During the printing process, the ink is spread on those plates by the cylinders, after which the image is printed on the material. It is necessary to do many calculations for the sizes of the cylinders, the sizes of the labels, and more. The preparation of the plates and the set-up required for Flexo is a very time-consuming process.

Turnaround time

According to these descriptions, it is possible to conclude that printing using Digital technology is much faster and easier than when using Flexo. As far as the speed of printing itself goes, Flexo works approximately 2-4 times faster. This has a major impact on the quantity of labels, such as when printing 10 million labels or more.

Due to these technological differences, the logic behind the work itself is also different, which means that the turnaround time for average label quantities using Digital technology printers is only several days, but the turnaround time for Flexo is several weeks.

Cost

As mentioned above, Flexo is a very difficult and time-consuming process in comparison to Digital. Therefore, it is also very costly, which has an impact on the wholesale price of the labels. Another factor that impacts the price of the labels used for Flexo is the number of designs used for the label. If you have labels that need many types of designs, the appropriate number of printing plates need to be prepared, which results in more time required for set-up and a higher cost.

Therefore, if you have an order that requires the use of many designs and between 10-20 million overall labels, Digital printing is the best option for you.

Flexo would be more affordable, however, if you do not have many designs but need a lot of labels.

Materials and surface treatment

With regard to the materials, both technologies have almost the same opportunities aside from several instances where one may have an advantage over the other. As of today, it is possible to use the same materials for Digital technology as it would be for Flexo technology. The only difference is that production companies may use specific material treatments for different materials so that no issues with quality will arise when using Digital technology.

There are no issues with lamination and varnish when either technology is used.

There is one advantage to using UV inkjet, which is that the ink used in UV inkjets is scratch resistant. Therefore, there is no need for any surface treatments if you don’t want any. However, surface treatments are mandatory if using the inks provided by other technologies.

Inks

The choice between inks when using Digital printing is much more limited than when using Flexo technology. We have four main colors for Digital printing: CMYK + White, which are bright and vivid and you can get smooth gradations without drop-off. They have great coverage, and it is possible to achieve Pantone colors with 97% similarity using the primary colors. At the moment, production companies are offering 3-4 additional inks that can be different Pantone inks. There is a larger variety of options for Flexo printing. It is possible to print any Pantone color with Flexo, including metallic colors and more. Of course, it also has its flaws with coverage, the smell of the paint, and more.

Now that you are more informed about the Digital and Flexo technologies, you will be able to make a better decision and find the best solution for your project. For more information, feel free to contact us and we will be happy to help you with your projects